Build & Learn: Humble Park Place Construction Types & Masonry Details

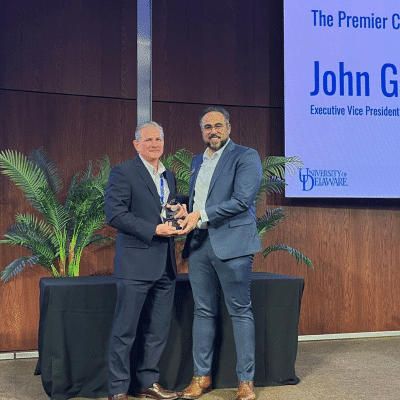

September 10, 2024 2:42 pmAt BPGS Construction, continuous learning is a crucial part of the company culture. BPGS is dedicated to empowering associates with knowledge to further their careers while also fostering an environment of comradery. Through the years, the team has developed strategic Build and Learn sessions in which all associates gather at a current job site for a lesson on unique aspects of the project or discussion on how an obstacle was overcome.

In July, Senior Project Engineer David Summerfield discussed the construction types and masonry details featured at Humble Park Place in Wilmington, DE. The project is a 63,000 SF apartment community ranging 4 to 6-stories and 61-units. The building consists of a Slab-on-Grade (SOG) with cold-formed metal framing on level one, a ComSlab Elevated Deck on level two, and wood framing on levels two through six. The façade consists of brick, fiber cement, Exterior Insulation Finishing System (EIFS), and aluminum windows.

CONSTRUCTION TYPES:

Construction types refer to one of five categories, each defined by its level of fire safety. Floor 1 of Humble Park Place is defined at 1A – Fire Resistive Non-Combustible and levels 2 and above are considered 3A – Protected Combustible.

- 1A – Fire Resistive Non-Combustible

- Non-Combustible materials will not ignite, burn, support combustions, or release flammable vapors when subject to fire or heat. 3-hour burn time.

- Highest level of fire-resistance-rated construction; structure is constructed with highly durable materials to withstand high temperatures for an extended period of time

- Materials: Protected Steel and Reinforced Concrete

- Elements include: structural frame, exterior and interior bearing walls, exterior and interiors non-bearing walls and partitions, and floor and roof construction

- 3A – Protected Combustible

- Combustible materials will ignite and continue to burn once flame source is removed

- Mixed combustible and noncombustible elements

- Exterior (non-combustible) – Masonry

- Interior Structure and Roof (combustible) – Wood

MASONRY:

The brick façade at Humble Park Place is made using four different types of brick and a granite. The BPGS team worked with DIGSAU and engineers to devise a plan to have the façade supported on each of the 4-6 stories.

- Brick Ledge: Reinforced concrete bearing which supports the weight of the brick directly on the footing. Poured monolithically with the foundation elements. Since the grade is sloped around the building, the elevation in which the ledge is poured must be reviewed so that the amount of brick buried below grade is limited and material isn’t wasted.

- Brick Relief Angle: A steel angle which supports the expansion and contraction of the brick coursing. The angle is fastened to the structural frame to support the brickwork for that floor. There is a relief angle on every level spanning the full length of the building on each side.

- Loose Lintel: An angle that provides support of brickwork over a masonry opening and is supported by bearing directly on the masonry jambs on each side of the opening. Refer to the design documents to determine bearing requirements and lintel sizes.

- Cast Sill: Located at each window, they provide the structural seating for the window frame which prevents water ingress, and are sloped outward to direct rainwater away from the window frame. Given the sills were manufactured, the size (length and depth), color, and profile of each sill was coordinated with the elevation and window type where it is being installed prior to fabrication.

- Mortar Joints: The spaces between the bricks which are filled by mortar or a grout mixture. The type of mortar joint chosen will determine the overall appearance of the surface. Mortar joints also ensure watertight properties and preserve the structural integrity.

- Lip Brick: Specialty shaped brick units with recesses cut into them to accommodate the lintel, leaving a lipped edge to cover the steel edge.

Humble Park Place is set to open Fall of 2024!

If you’re looking for a company that encourages continuous learning and real-world applications, click here for current opportunities!